Shuanghao is a famous China Bottle Cap Cutting Machine manufacturers and China Bottle Cap Cutting Machine suppliers. Our factory specializes in manufacturing of Bottle Cap Cutting Machine. Our business consists of two main categories:machinery series and injection moulds.We produce various plastics, PET preform moulds and daily commodity moulds. We have just successfully developed some steel moulds for use in SMC, BMC, and stretching procedure.

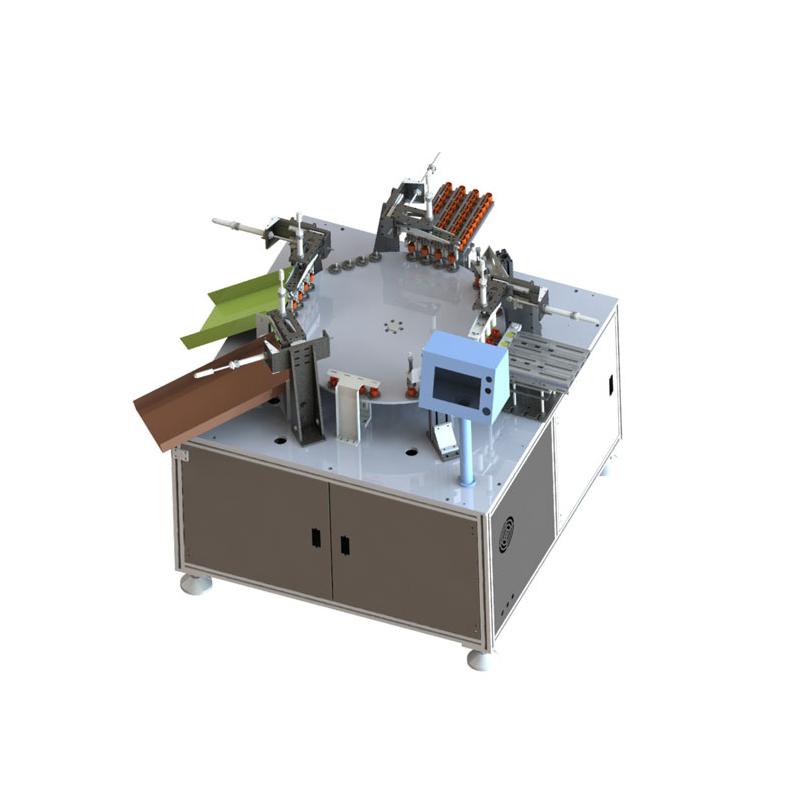

Bottle Cap Cutting Machine combines the capacity of folding and cutting, optimizes and integrates both machines advantage into one small, highly-productive machine.

The Bottle Cap Cutting Machine can complete the procedures of adding caps,sorting caps,feeding caps,cutting rings,dropping caps and distributing caps to separate boxes.

The Bottle Cap Cutting Machine can be used for small-scale production of bottle caps and is the first choice of major mineral bottle cap and beverage cap manufacturers.