With over a decade of manufacturing experience in the automatic cap molds industry, we are confident with our high-quality products helping you achieve your company goals. Allow Shuanghao molds to supply your bottle cap molds requirements and experience the superior difference with our advanced equipment.

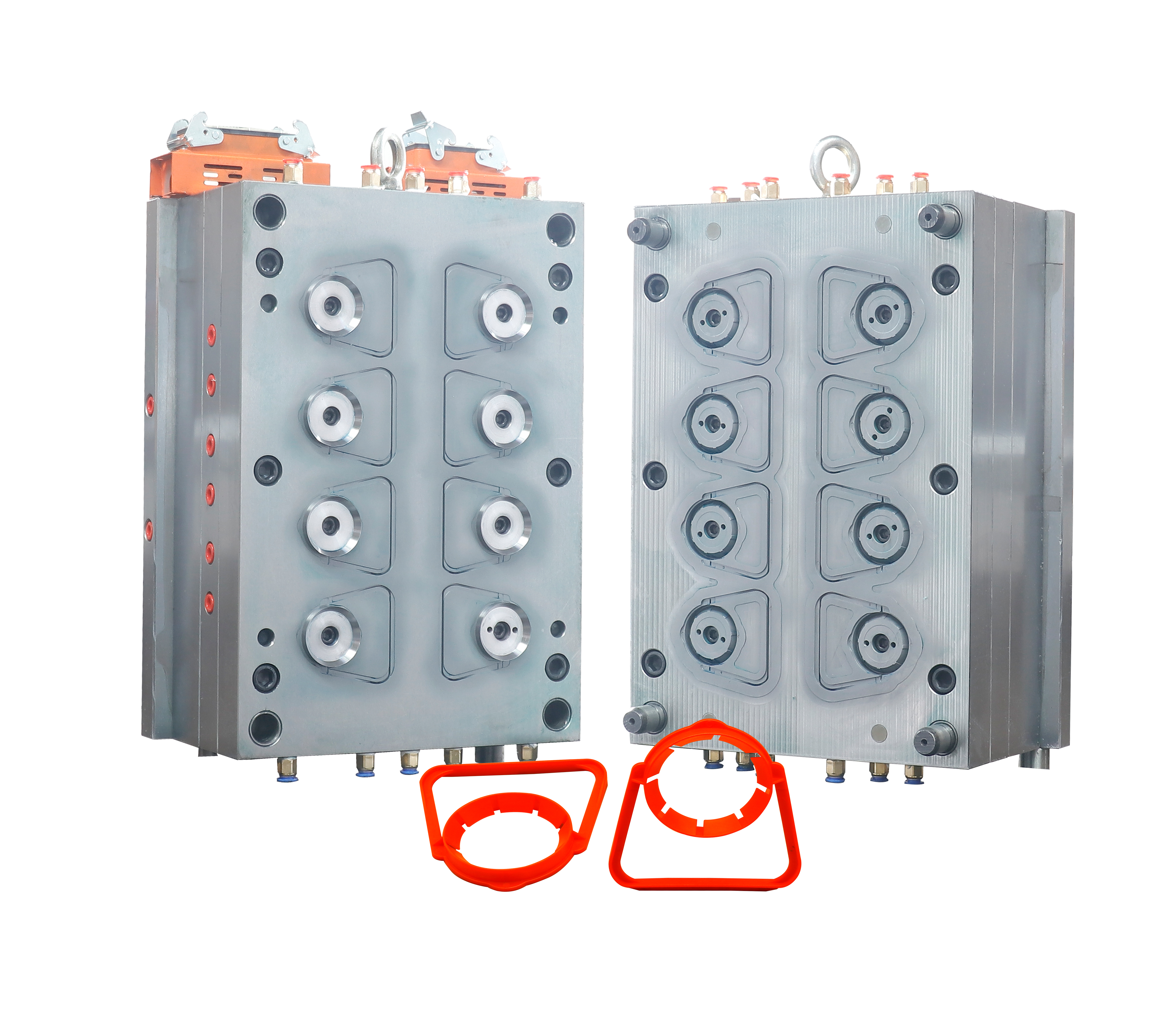

A cap mold, also known as a cap mould, is a specialized mold used in the manufacturing process of caps or closures for bottles, containers, or other packaging products. It is designed to create the specific shape, size, and features of the cap, such as the threads, tamper-evident bands, and sealing mechanisms.

We aim to help our customers improve their production efficiency and profitability. Our primary clientele includes plastic water bottle factories, oil bottle cap packing manufacturers, and cosmetic packaging bottle cap servicers. Our cap molds are suitable for professionals in the packaging industry.

With our cap molds, expertise, and high-quality services, we want to maximize our customers’ productivity. Shuanghao cap molds clients can expect improved performance, quality, safety, flexibility, and its molds overall economy.

Automatic flip top cap Molds structure is more difficult than normal caps, the mold ejection system is special and have double steps. the cap closing success rate is very important to the Mould.

Shuanghao is the cap Molds maker in China, who can make 24 cavities flip top caps mould with automatic closing system. Automatic production equipment is much more safer than human made. And it will help save cost in employee labors. Full automatic is international trend toward. If you want to improve your injection equipment, welcome contact me free. We are flip top caps mould China and looking for more and more partner all over the world.

Plastic Mineral Water Cap Mould hallmarks include extremely fast cycle times, (sometimes less than 2 seconds). Mold cooling becomes extremely important to achieve these cycles as well as a smooth and even ejection of the parts from high cavitation molds which are some of StackTeck’s strengths.We specialized in designing and manufacturing plastic cap mold, PET preform mold, blowing mold with our own mould factory.AD/CAM/CAE system for designing and engineering mould products.We design and use standard moul frame and use pricision 3D printer and CNC tooling machine to make parts, in order to ensure the quality of the moulds. We also wholesale Plastic cap, other molds and service.

aximize your 5 gallon water caps output - superior closure solutions for efficient 5 gallon water cap molds offered by shuanghao that has done a huge of different caps and closures projects, a division of Shuanghao Mould, are here for you! You will get the excellent 5 gallon water cap mold with full support from the cap design to mass production on your factory. shuanghao has delivered hundreds of high performance 5 gallon water bottle cap molds reputed among customers.

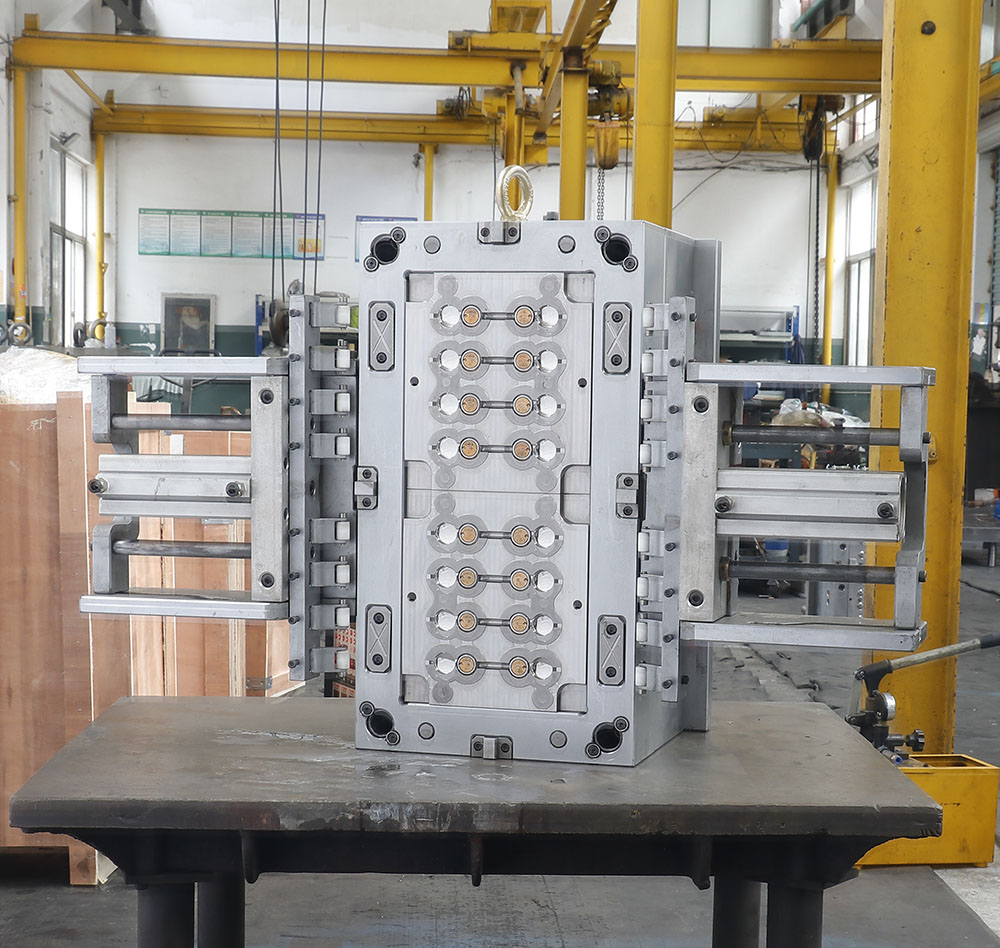

We take pleasure to introduce ourselves as the leading manufacturer and supplier of an excellent quality range of Plastic Handle Mould in the market. Offered mould is manufactured at our hi-tech manufacturing unit under the direction of highly accomplished professionals in compliance with the industry quality standards. To meet the set industry quality standard, offered Plastic Mould Handle is tested on various quality parameters by our experts. Further, these moulds are used for making various plastic handles .

Shuanghao mould factory has been manufacturing oil bottle cap mould for many years. We devoted ourselves to cap mould, caps moulds injection mould, which are sold in more than 60 countries and areas.

We sincerely hope to establish good and long-term cooperation with customers all over the world! Pioneers in the industry, we offer Plastic Bottle Cap Mould Die, Plastic Cap Mould Die, Cap Mould Die and 28mm Plastic Cap Mould Die from China.

Besides being an excellent manufacturer and supplier of cap molds machines, we are proud to offer services associated with the machines we provide. We combine our research development, design, manufacturing, and sales expertise in providing traditional and modern container designs that suit any business’s needs.

Our plastic water bottle-making molds are suited for developing containers for nearly all other types of liquids. We can supply products to hold juice, energy drinks, tea, coffee, and soy sauce. Get in touch with our experts to discuss your company’s specialties and determine the best service for your products.

Experience the superior difference in your packaging needs with Shuanghao molds. With Cap molds that improve productivity, we ensure your company produces the molds it needs. Connect with our specialists to discuss your organization’s goals in the packaging industry.

[Call Us]

Safety Gear: Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and protective clothing when handling the mold or working with mold components.

Proper Installation: Install the cap mold correctly, according to the manufacturer's instructions, to avoid any misalignment or damage to the mold components.

Avoid Overloading: Do not overload or overwork the cap mold beyond its capacity. Follow production guidelines and recommended cycle times to avoid damage to the mold and ensure consistent production quality.

Use Correct Materials: Use only appropriate materials approved for use with the cap mold to avoid any unwanted chemical reactions or damage to the mold.

Proper Cooling: Ensure that the cap mold is properly cooled to avoid overheating, warping, or deformation of the mold and resulting in poor quality caps.

Regular Maintenance: Perform regular maintenance of the cap mold as recommended by the manufacturer to maintain optimal performance and avoid any unexpected downtime or production issues.

Proper Storage: Store the cap mold in a clean, dry environment, away from any potential contaminants, and protect it from dust, moisture, and extreme temperatures.

Operator Training: Provide proper training to operators to ensure they understand the correct procedures for using the cap mold, including loading and unloading, cleaning, and maintenance.