Shuanghao Mould is the famous Chinese cap mould maker which specialized in producing water cap mould and bottle cap mould. We can offer you different kinds of plastic cap mould solutions, eg, automatic unscrewing ejection cap solution, bi-injection system cap solution, complex flip top cap solution and irregular shape design cap solution.

We have long history and rich experience in making bottle cap mold. With the advantage of Stavax S420 for core and cavity, P20 for mould base, our cap molds have the longer mould life and durability.

In order to become the biggest bottle cap mould maker in china, we devoted to keeping high quality in cap molds. Our flip-top cap mould used Stavax S420 stainless steel, tempered with HRC55+/-2 with maximum mould life. We also have various shape design and size for your special plastic cap mold demand.

Shuanghao Mould is your best choice if you are looking for a credible cap mould company. We could offer you high quality and reasonable price mould.

Please contact us. We offer you not only a mould, but a fine solution…….

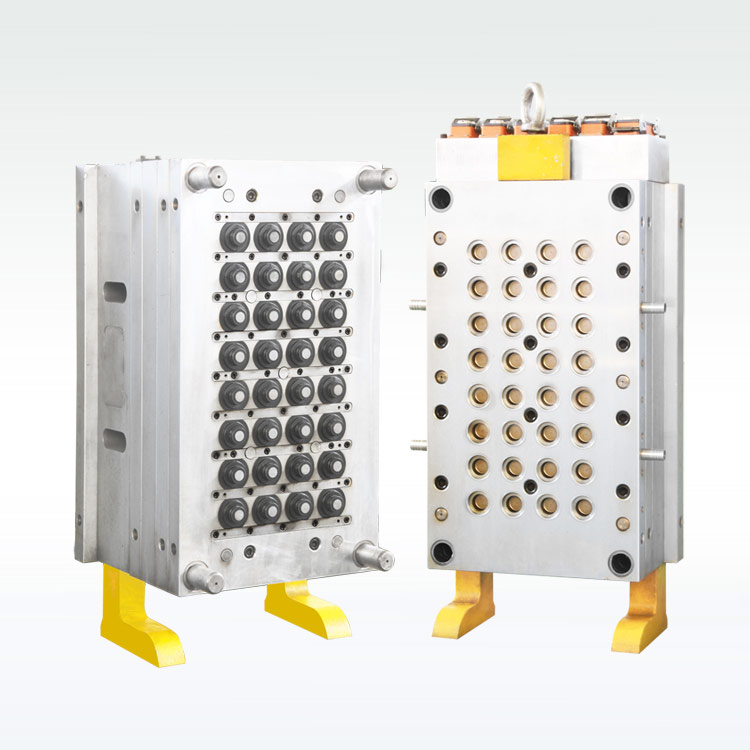

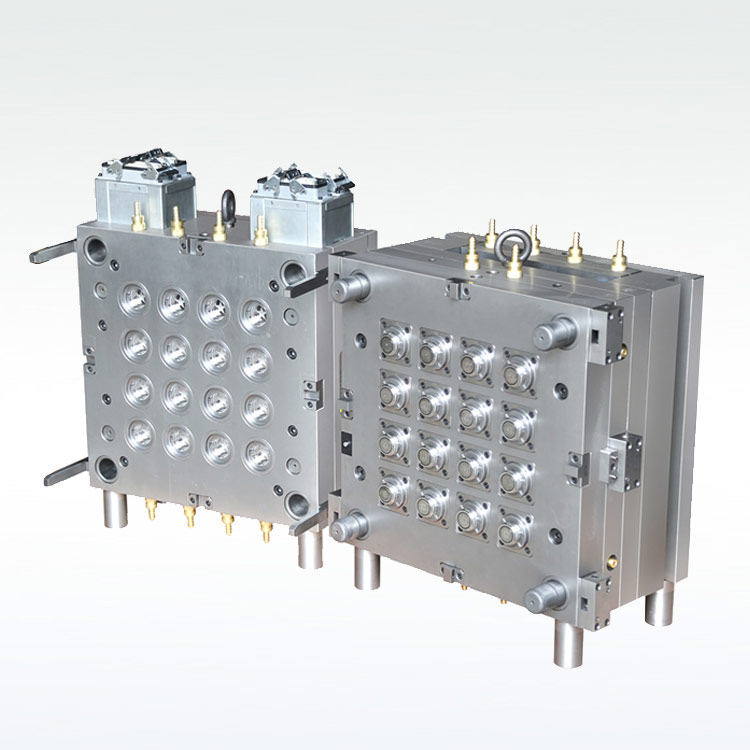

Mould Name :Oil bottle Cap mould

Cycle Time: 9s/stroke

Mould Life: 10 million shots

Mould Steel Material: Core & Cavity: Stavax S420, Mould Base: P20

| Product Name | Plastic Oil Caps Injection Mold |

| Plastic Material | PPR,PP, PP+GF, PP+ TALC,PE,ABS,POM,PPH…etc. PC, PS, PMMA for Transparent. |

| Steel of Cavity & Core | Depends on Product, we help customer to choose the suitable material. Commonly used material as below: Buderus: 1.2311, 1.2738, 1.2344, 1.2316, BPM-HH, SUS-420…etc. Finkl: P20, HiP-20, H13…etc. Hitach: NAK80, DAC, FDAC, SKD61…etc. Assab: 618, 718, STAVAX…etc. |

| Steel of Mold Base | Depends on Product, we help customer to choose the suitable material.Commonly used material is S50C. |

| No. of Cavity | Customized |

| Hardness of Cavity & Core | Pre-Hardness Steel: HRC 30 ~ 32 ± 1° Heat Treatment Steel: HRC 50~52± 1° |

| Core pulling or Ejection system | Depends on the Product. Commonly used : Motor, oil cylinder, stripping plate, angel pin, ejector pin…etc |

| Mould Accessories | Compatible to DME/HASCO Standard. |

| Cooling System | In Core: Baffle or By pass cooling In Cavity Plate: Chain drilling type cooling |

| Surface Finish | Depends on the product. Commonly used: Texture Hatching, EDM Hatching, Polishing, Diamond Polishing…etc. |

| Mold Life | Depends on the steel hardness and the plastic material. Commonly used: 300,000 ~ 500,000 shots or 1 year under normal use procedure for Pre-Hardness material. 1,000,000 shots or 1 year under normal use procedure for Heat Treatment material. |

| Runner | 1. Cold Runner. 2. Hot Runner. |

| Delivery time | Depends on the product size and complication. For First trial: 45 ~ 80 days after mold drawings approved. |

| Packing | Standard Wooden Case |

| Machine Center | CNC milling machine, CNC Lathing machine, EDM, NC milling & lathing machine and so on. |

| R & D | We offer customers the drawings for products and mold design. Also we provide extra service such as: Reversing Engineering Drawing, Optical Design, Photometric Design… etc. We can work with 2D/3D drawings or with provided samples. |

| Production | We can also provide Pilot Run production and molding production. |