Shuanghao mould factory has been manufacturing oil bottle cap mould for many years. We devoted ourselves to cap mould, caps moulds injection mould, which are sold in more than 60 countries and areas.

We sincerely hope to establish good and long-term cooperation with customers all over the world!

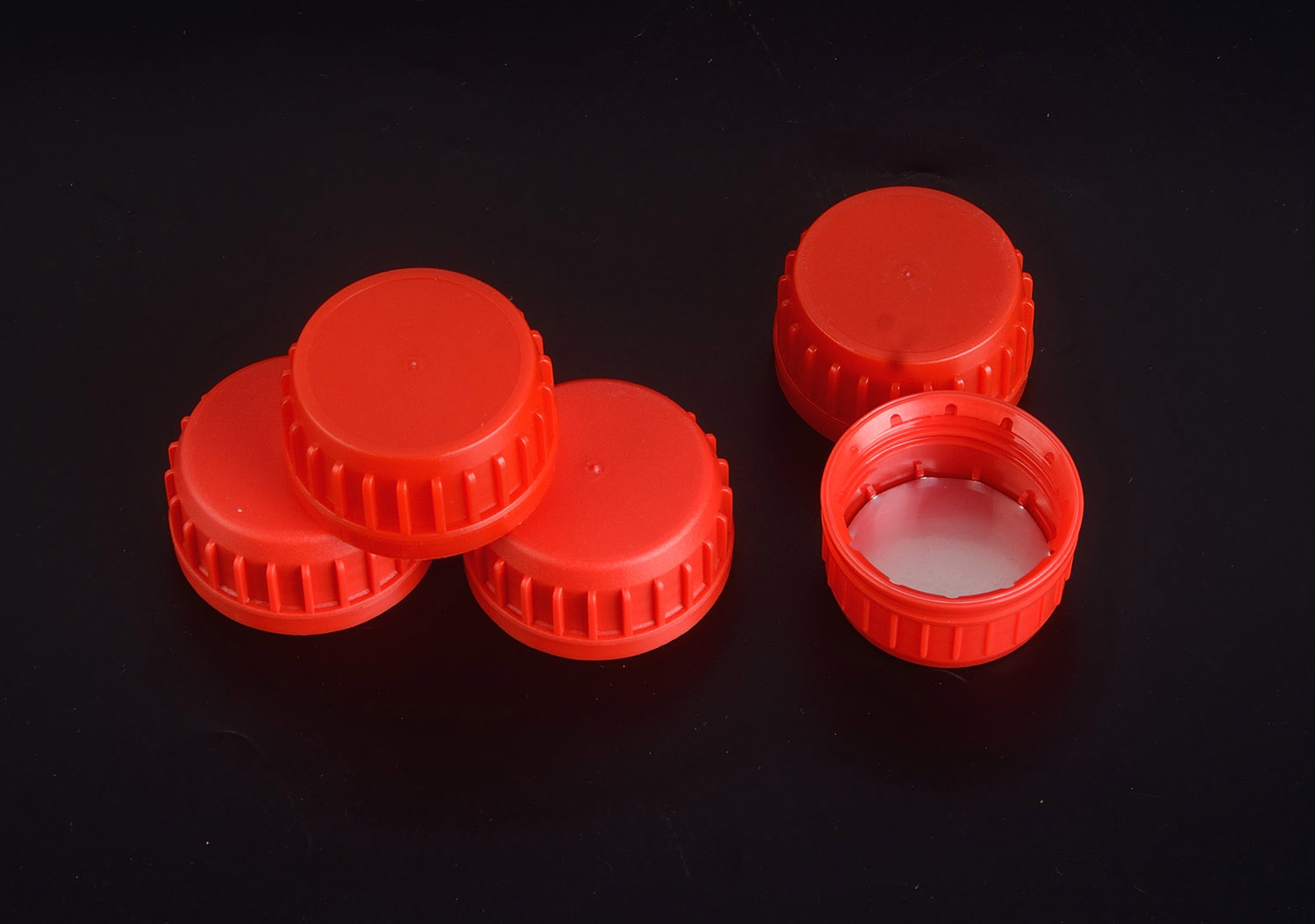

Pioneers in the industry, we offer Plastic Bottle Cap Mould Die, Plastic Cap Mould Die, Cap Mould Die and 28mm Plastic Cap Mould Die from China.

Shuanghao mould factory has been manufacturing oil bottle cap mould for many years. Wedevoted ourselves to cap mould, caps moulds injection mould, which are sold in more than 60 countries and areas.

We sincerely hope to establish good and long-term cooperation with customers all over the world!

Pioneers in the industry, we offer Plastic Bottle Cap Mould Die, Plastic Cap Mould Die, Cap Mould Die and 28mm Plastic Cap Mould Die from China.

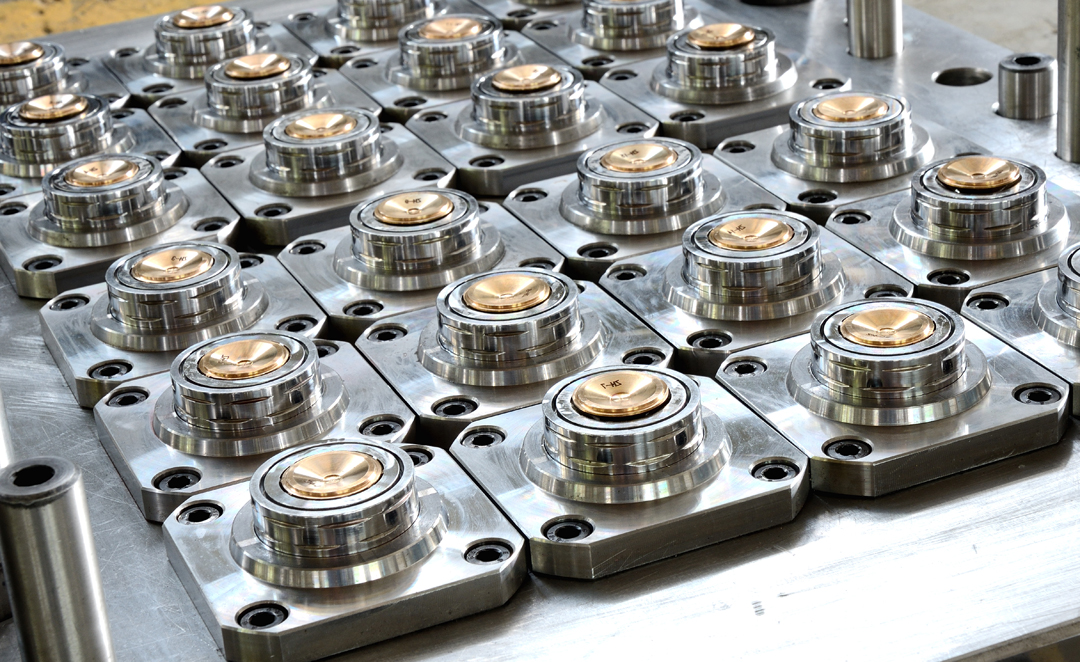

Aim of the technology developed by Shuanghao mould is to reduce the cycle time to the bare minimum. Shuanghao mould for production of closures for soft-drinks, mineral water, milk, juice, oil, spirit, cream and many other products are now among the most performing both for productivity and reliability.

We have significant experience in the manufacture of cap moulds for different types of closures by customer's demand.

Lightweight Caps:-Mineral water cap mould,Beverage cap mould,5 gallon cap mould,Theft proof cap mould,Shampoo cap mould,Different kinds of oil cap mould

,Sport cap mould,Cosmetics cap mould,Wine cap mould.

| Product Name | Plastic Oil Caps Injection Mold |

| Plastic Material | PPR,PP, PP+GF, PP+ TALC,PE,ABS,POM,PPH…etc. PC, PS, PMMA for Transparent. |

| Steel of Cavity & Core | Depends on Product, we help customer to choose the suitable material. Commonly used material as below: Buderus: 1.2311, 1.2738, 1.2344, 1.2316, BPM-HH, SUS-420…etc. Finkl: P20, HiP-20, H13…etc. Hitach: NAK80, DAC, FDAC, SKD61…etc. Assab: 618, 718, STAVAX…etc. |

| Steel of Mold Base | Depends on Product, we help customer to choose the suitable material.Commonly used material is S50C. |

| No. of Cavity | Customized |

| Hardness of Cavity & Core | Pre-Hardness Steel: HRC 30 ~ 32 ± 1° Heat Treatment Steel: HRC 50~52± 1° |

| Core pulling or Ejection system | Depends on the Product. Commonly used : Motor, oil cylinder, stripping plate, angel pin, ejector pin…etc |

| Mould Accessories | Compatible to DME/HASCO Standard. |

| Cooling System | In Core: Baffle or By pass cooling In Cavity Plate: Chain drilling type cooling |

| Surface Finish | Depends on the product. Commonly used: Texture Hatching, EDM Hatching, Polishing, Diamond Polishing…etc. |

| Mold Life | Depends on the steel hardness and the plastic material. Commonly used: 300,000 ~ 500,000 shots or 1 year under normal use procedure for Pre-Hardness material. 1,000,000 shots or 1 year under normal use procedure for Heat Treatment material. |

| Runner | 1. Cold Runner. 2. Hot Runner. |

| Delivery time | Depends on the product size and complication. For First trial: 45 ~ 80 days after mold drawings approved. |

| Packing | Standard Wooden Case |

| Machine Center | CNC milling machine, CNC Lathing machine, EDM, NC milling & lathing machine and so on. |

| R & D | We offer customers the drawings for products and mold design. Also we provide extra service such as: Reversing Engineering Drawing, Optical Design, Photometric Design… etc. We can work with 2D/3D drawings or with provided samples. |

| Production | We can also provide Pilot Run production and molding production. |